Choose your industry!

No matter what your bore sizing challenge may be, anywhere in the world, we have the “Sunnen Solution” for you!

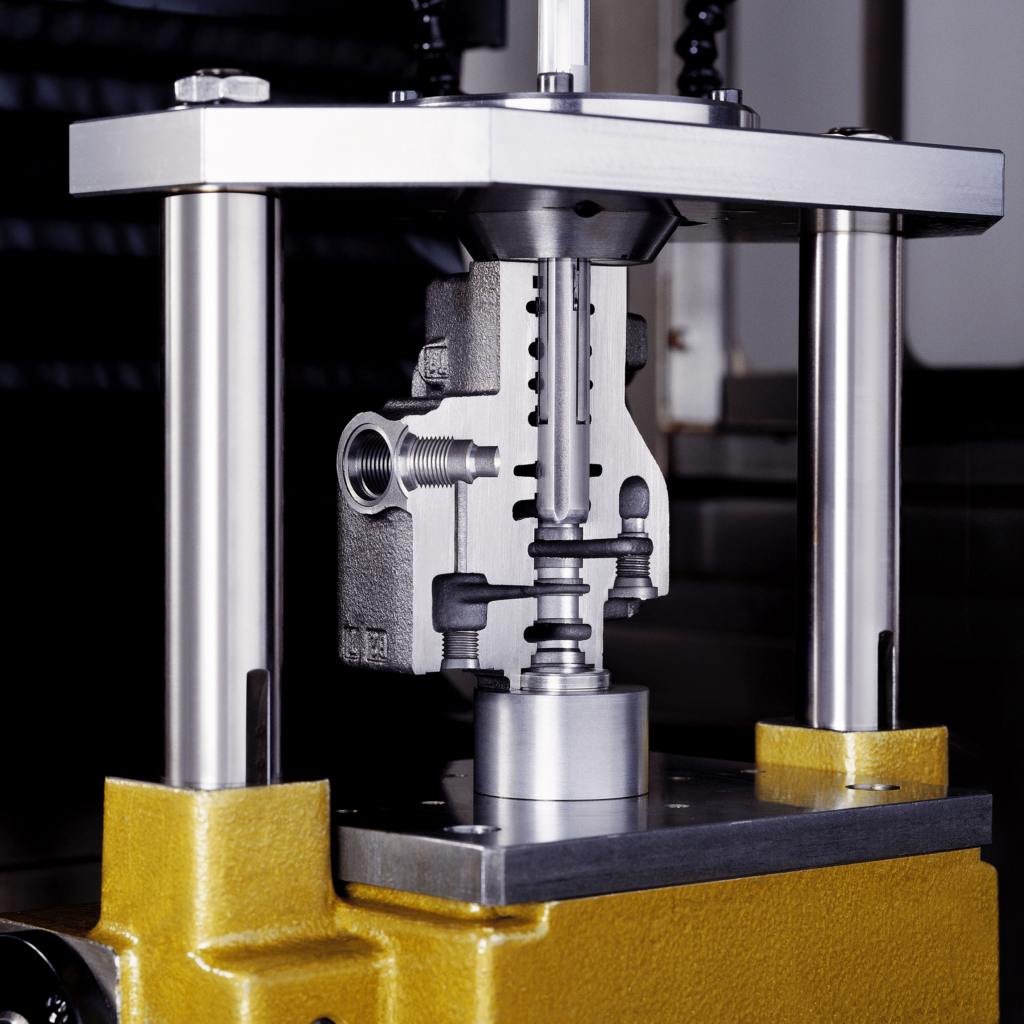

Hydraulic Applications:

Axial Piston Pumps, Hydraulic Blocks, Valves and Hydraulic Cylinders

Sunnen solutions

Energy Production Applications:

Oil & Gas Components, Wind Mills, Turbines

Sunnen solutions

Aviation Applications:

Landing Gears, Turbines, Pressure reservoires, Shaft for Jet Fans, Helicopter-Blade Control Shafts

Sunnen solutions

Car & Engine Components:

Motor Blocks, Small Engines, Injectors, Turbo Charger Housings, Common Rail Parts, Servo Steering Components, Brake Drums, Liners, Gears, Rocker Arms, Connecting Rods

Sunnen solutions

Machinery & Component Applications:

Gears, Machine Tool Components, Tool Holding Devices, Bearings, Collets, Carbide Bushings, Ceramics / Compound Material Parts, Measuring Equipments, Compressor Comp.

Sunnen solutions

Injection Molding Systems Applications:

Extruder (twin and single screw), Cavities for PET-Bottle Production, Manifolds, Punching Dies, Carbide Dies for Screw Manufacturing

Sunnen solutions

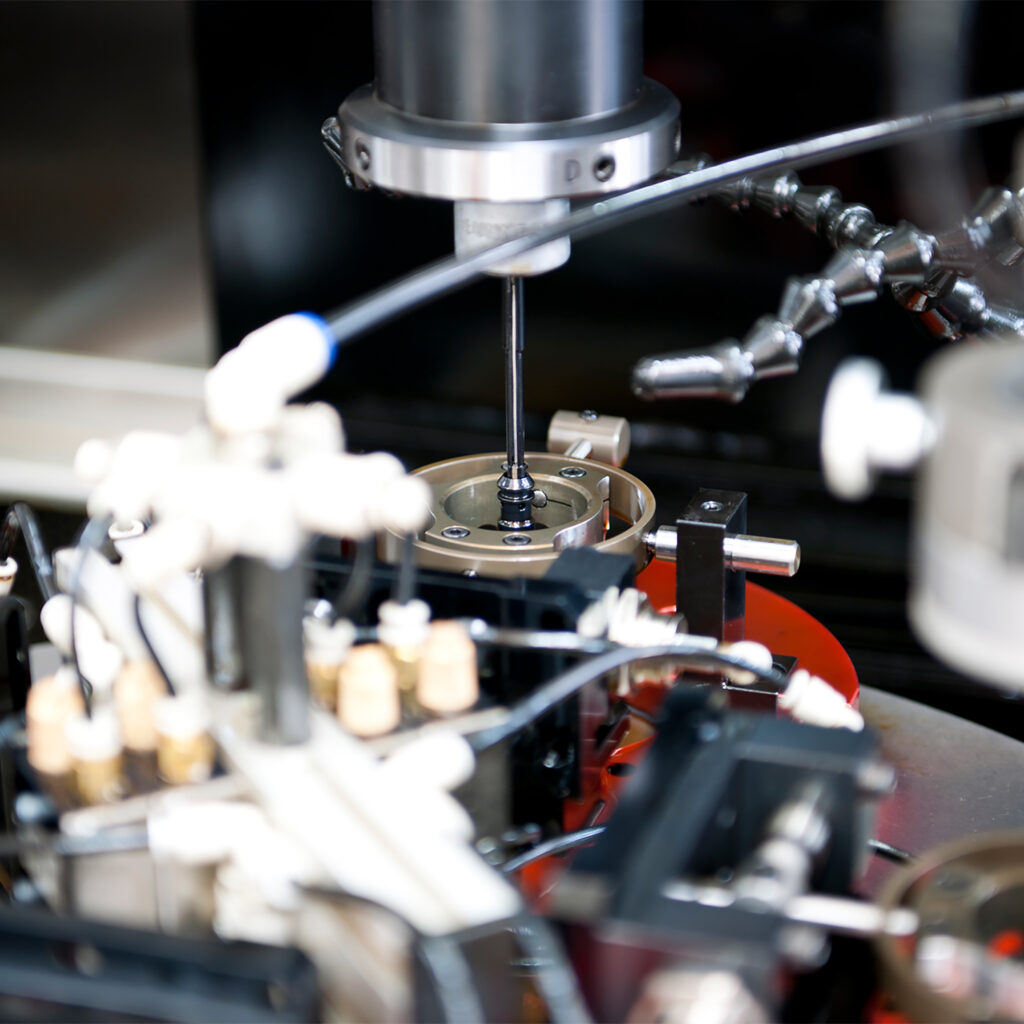

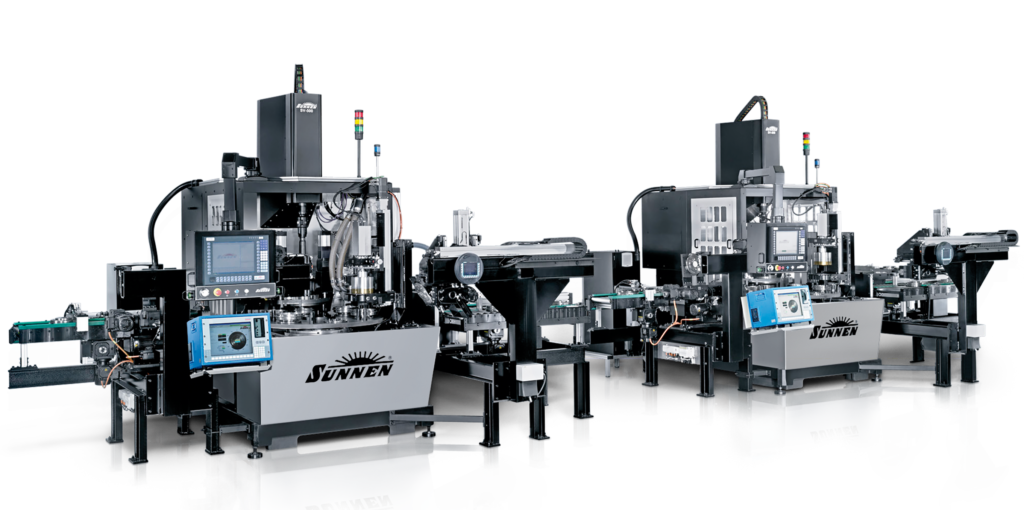

Automation

Produce more precise, faster and easier – We customize your individual system!

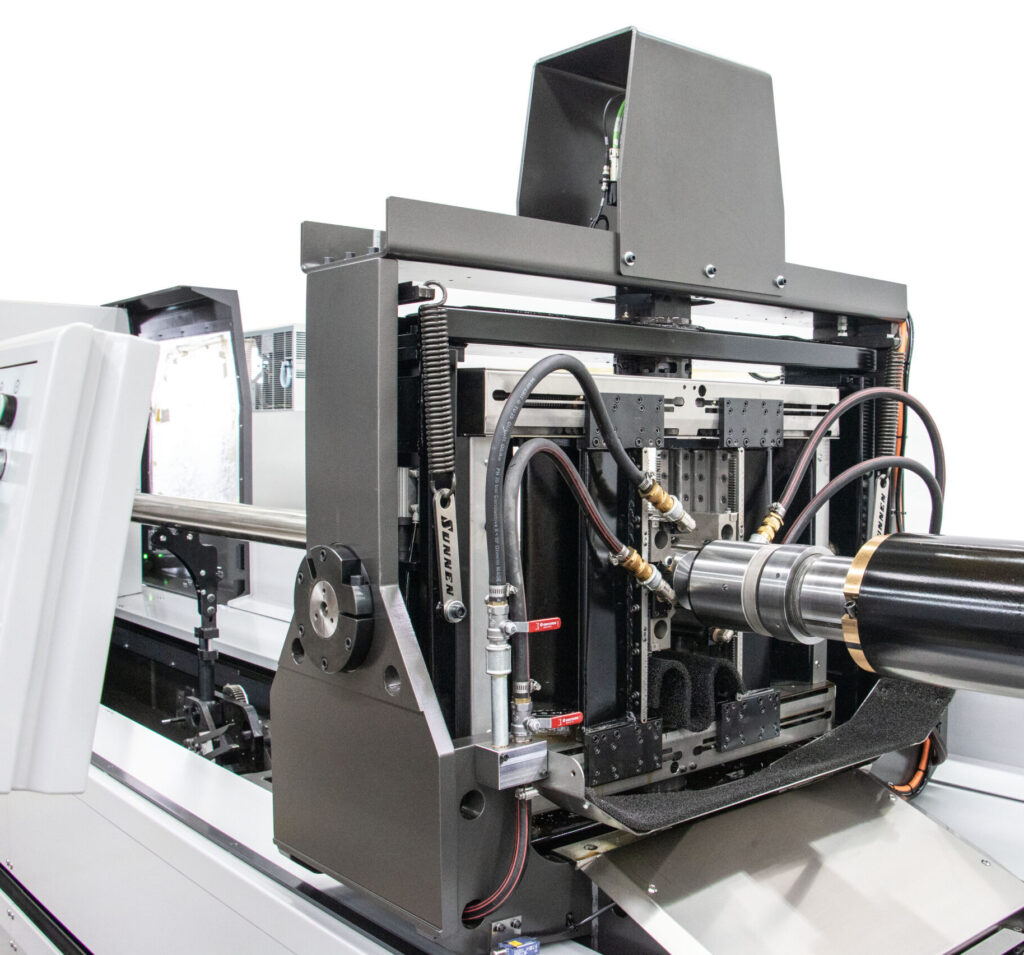

SV2010 V1

Two independent Sunnen SV2010 machines for roughing and finishing, connected with manual conveyor, automated clamping, processing of programmed hole pattern, postprocess measuring with feedback.

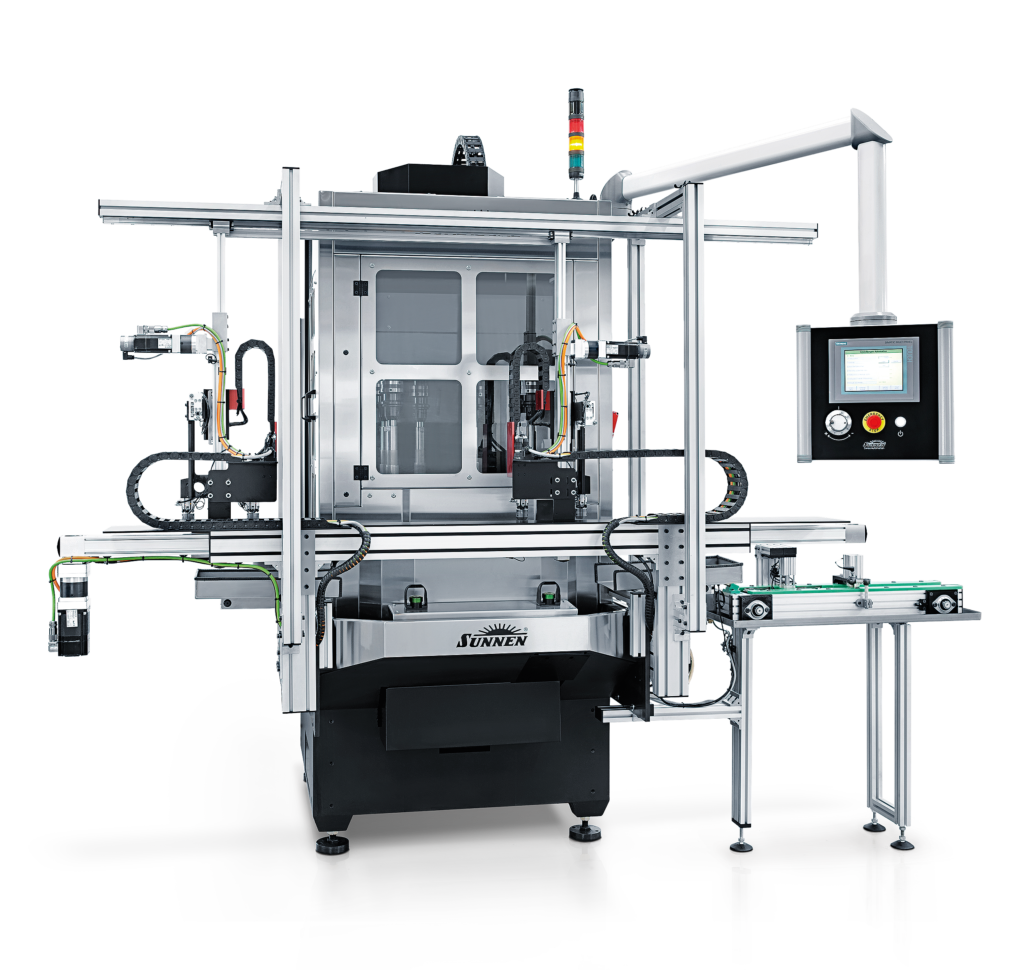

SV2015 V1

Sunnen SV2015 with loading / unloading unit, gantry type part handling system, external air measuring system, unique part holding system.

SV2015 V2

Sunnen SV2015 with large robot, part feeding conveyorbelt, 1 roughing- / 1 finishing- / 1 deburring-spindle inside machine, index table, external part spinning (cleaning) station.

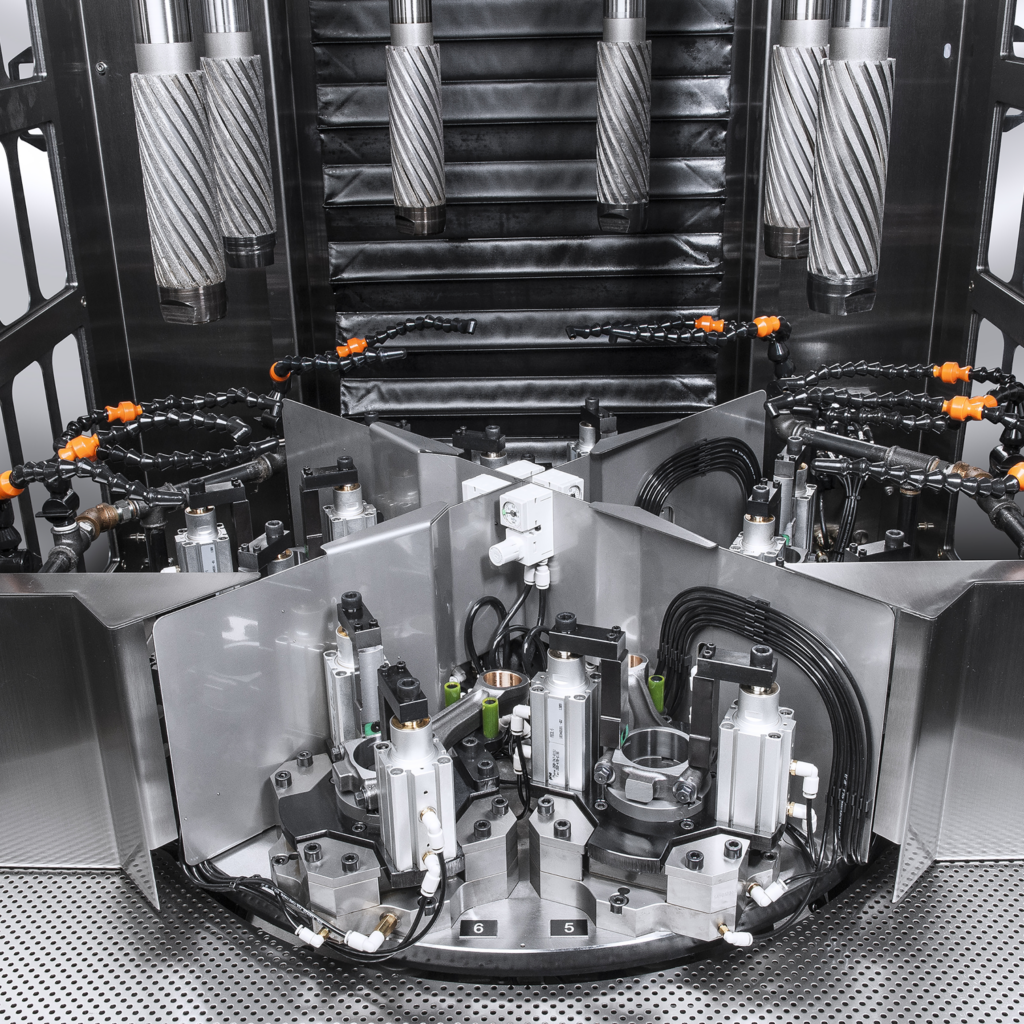

SV2015 V4

Sunnen SV2015 with robot, pallet changing system for 13-26 pallets, measuring station with feedback and index table for multiple operations, miscellaneous numbers of hydraulic valves.

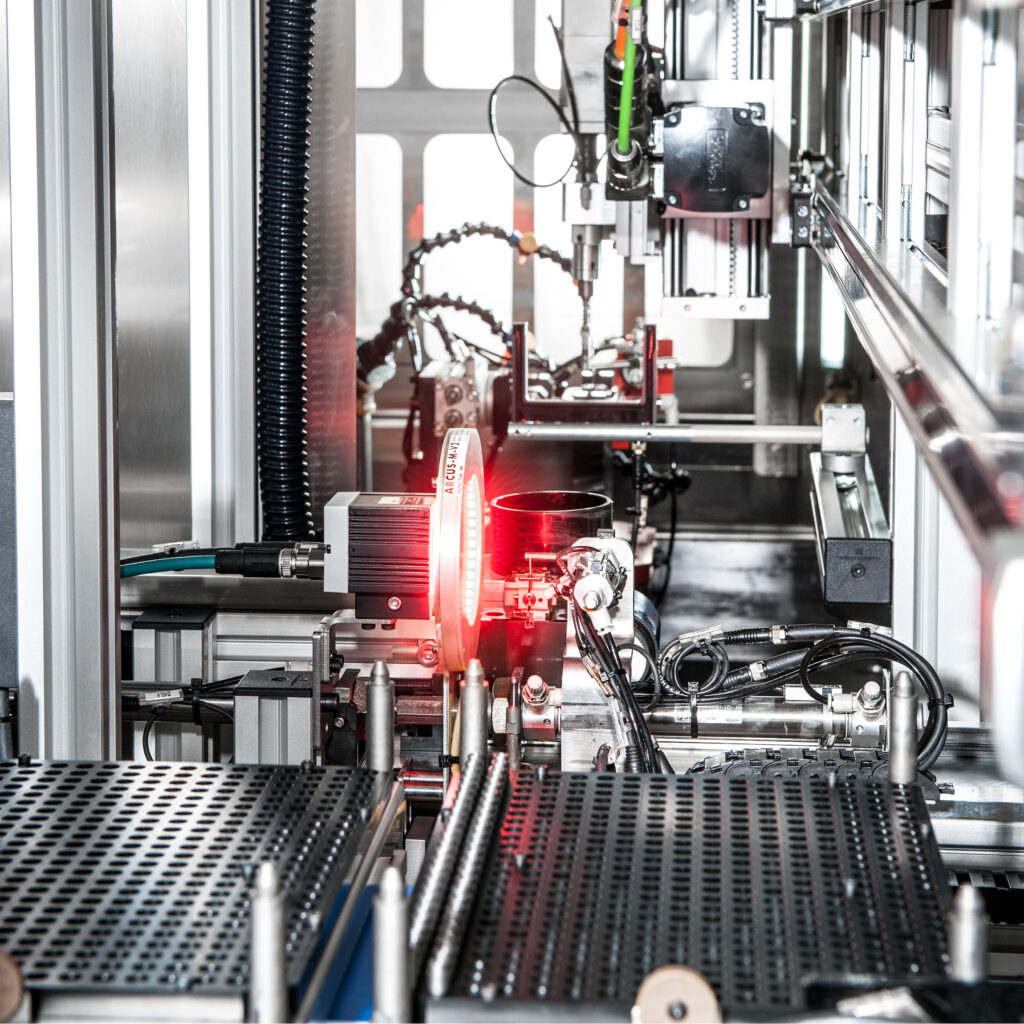

SV2015 V5

Two fully automated Sunnen SV2015 machines for roughing and finishing, connected with smart part handling system, visual part orientation unit, postprocess measuring with 100% feedback.

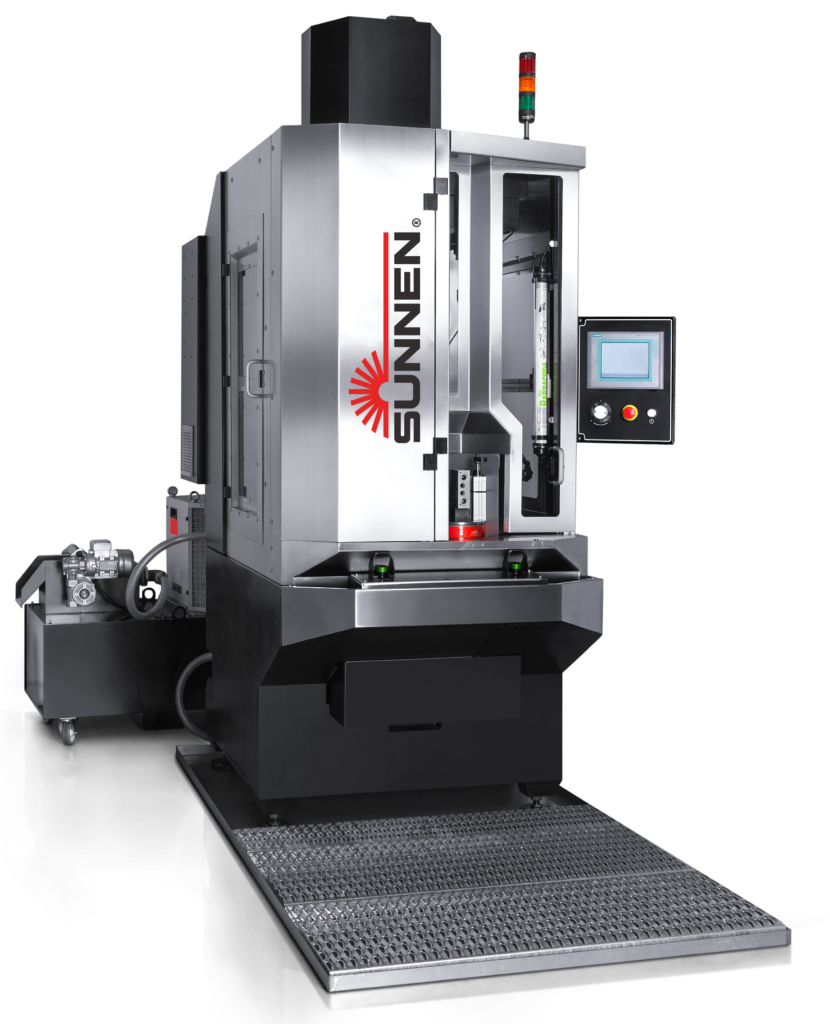

SV2490

Sunnen SV2490with customized machine housing, integrated oil mist filter, loading / unloading of heavy parts on automated linear table, processing of parts in a row in cycle, fixture capable to clamp various parts.

SV2500

System Solution for Brake Drums SV2500 with linear loading / unloading unit, part-orientation, index table inside machine for multiple operations such as loading / unloading, honing and measuring. Complete integration in the production line.

VSS286 V1

Sunnen VSS286 with linear-gantry, part separation unit, loading / unloading of two parts, double indexing of the rotary table inside the machine, high production solution integrated in transfer line.

VSS286 V2

Sunnen VSS286 with customized machine housing, independent infinitely variable brushing station, flexible clamping system for short setup changes.

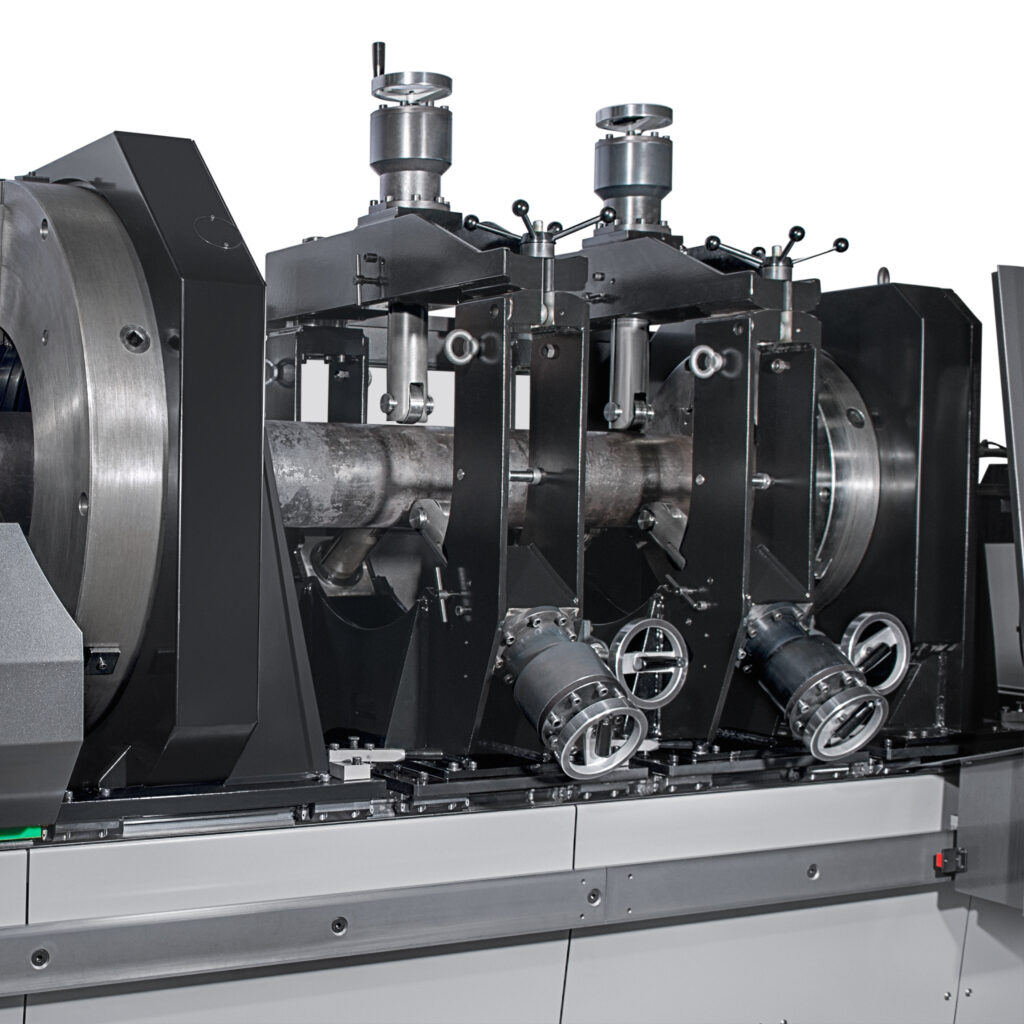

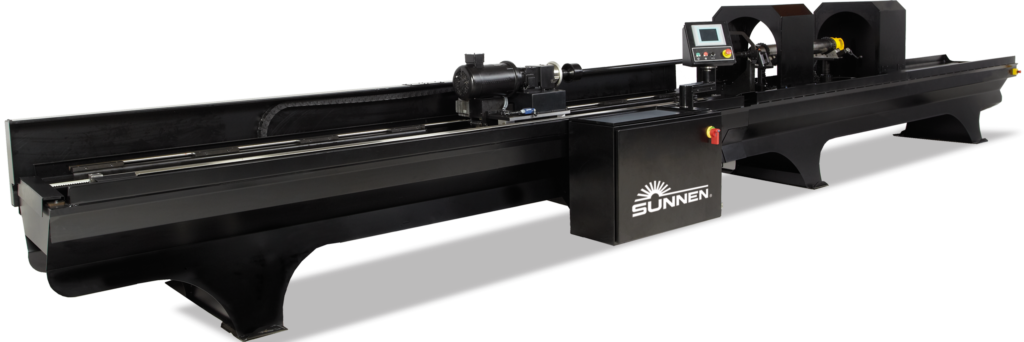

Tube Hones

Solutions for a large diameter range.

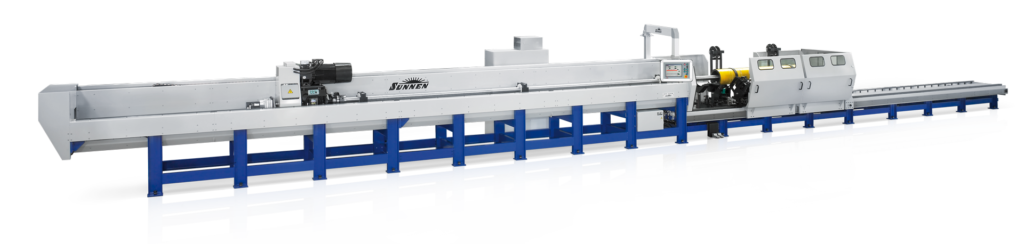

HES Serie

- Large diameter range

- Automatic correction of roundness and parallelity

- Operator-friendly, Windows ®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

HTB Series

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for repair & job-shop production

HTC Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Fast setup

- Excellent for production

HTC-x121

- Short setup and changeover time

- Automatic bore geometry correction

- Program memory for over 900 setups

- 100% process control with tool overload protection

- Operator-friendly Windows®-based monitoring system

HTD Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

- High stock removal up to 2’500 cm3/h

HTH Series

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for production

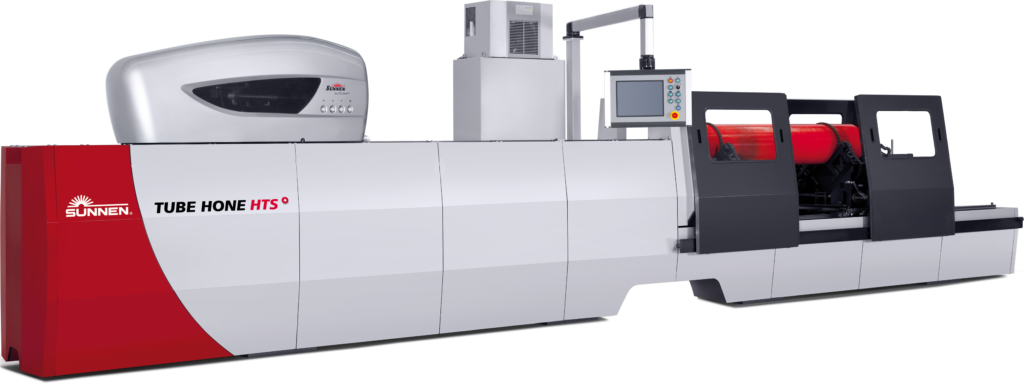

HTS Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

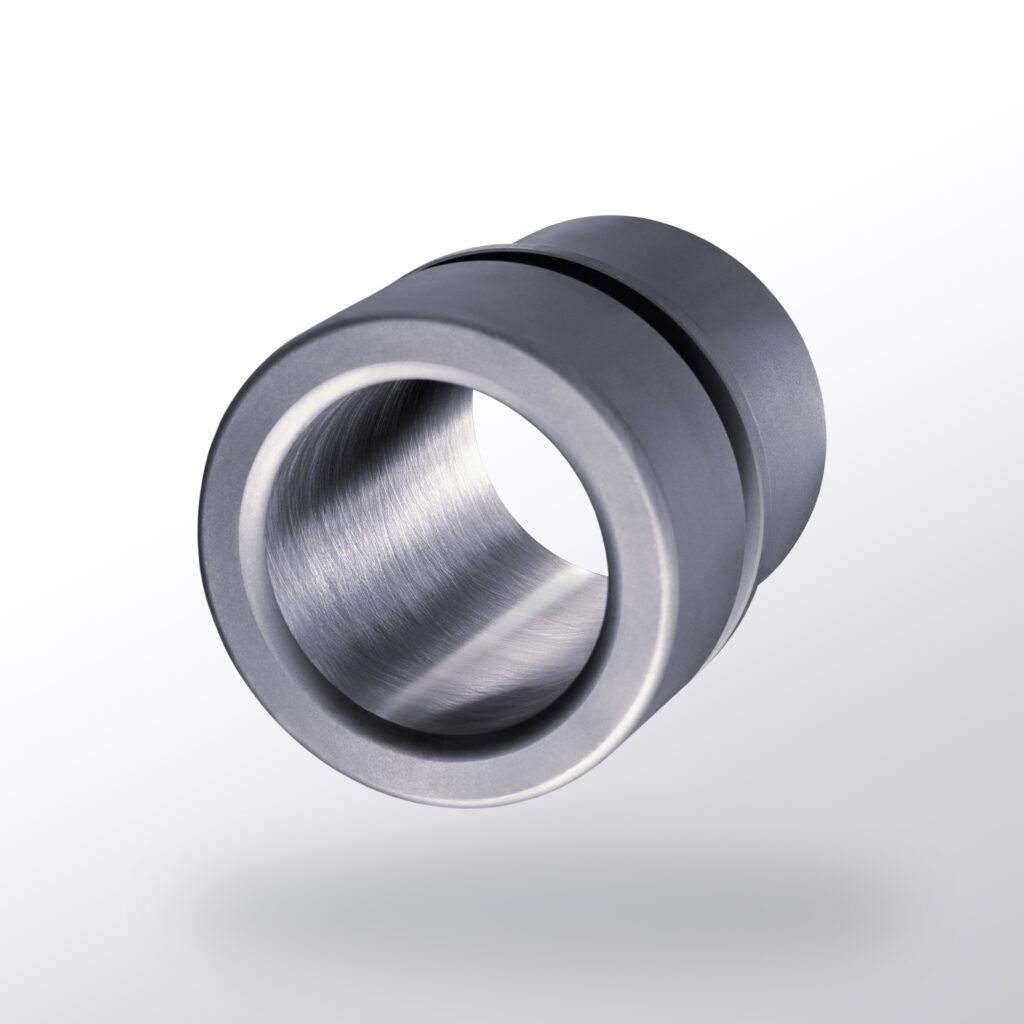

Honing

We have the “Sunnen Solution” for you.

SH2000

- Manual or semi-automated machine

- Universal workholding fixture

- Internal or external coolant tank

SV30xx/SV31xx Series

- Extended stroke length

- Index table

- Integrated measuring system

- Multi column

SV34xx Series

- Workpiece weight up to 900 kg

- X-axis with 1’143 mm travel

- Extended stroke length

SV35xx Series

- Workpiece weight up to 900 kg

- Linear feed system

- X-axis with 1’143 mm travel